3D printing: car equipment and accessories

The automotive industry takes advantage of the possibilities offered by 3D printing at every stage of production - from the prototype and tests to the production of spare parts and final elements. One of the best ways to use a 3D printer is to design and 3D print car accessories. It is not only functional, but also a unique design. What's more, 3D printing allows us to recreate a cheaper version of an existing product.

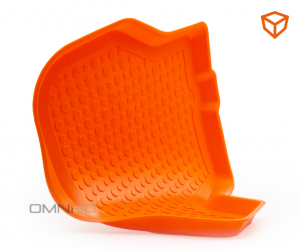

An example of a functional element for a car that has been printed in 3D technology is a waterproof, protective and designer car mat. Individually designed for the client’s needs, ideally suited to specific dimensions, it replaced the existing element of the car interior.

| SECTOR | Automotive |

| CATEGORY | Low volume production |

| FILAMENT | TPU-93A |

| PRINT TIME | 41:29h |

| WEIGHT | 531.78g |

| SIZE | 450x416x25 |

The possibilities offered by large-format 3D printing are used not only by individual customers, but also by automotive concerns, smaller workshops and car tuning companies. As the Omni3D case-study shows, the use of 3D printing in the automotive industry allows you to create lighter parts, much more durable and, most importantly, from a wide range of available materials.

Discover more automotive case studies from Omni3D: