What is fff 3d printing technology?

The FFF (Fused Filament Fabrication) or FDM (Fused Deposiotion Modeling) technology is a versatile 3D printing technique, whose characteristic feature is the extrusion of material in the form of a thick vein - a filament from the printing heads. Ease of use, optimal cost of implementation and durability of printouts make this 3D printing technology very popular in industrial applications.

3D printing in FFF, or Fused Filament Fabrication, consists of depositing layer after layer of melted material – filament. It’s a method of 3D printing used, among others, to create prototypes, tools, but also final products; it is used in such industries as aviation, architecture, automotive, molding, industrial design, medicine and many others.

FFF 3D printing technology

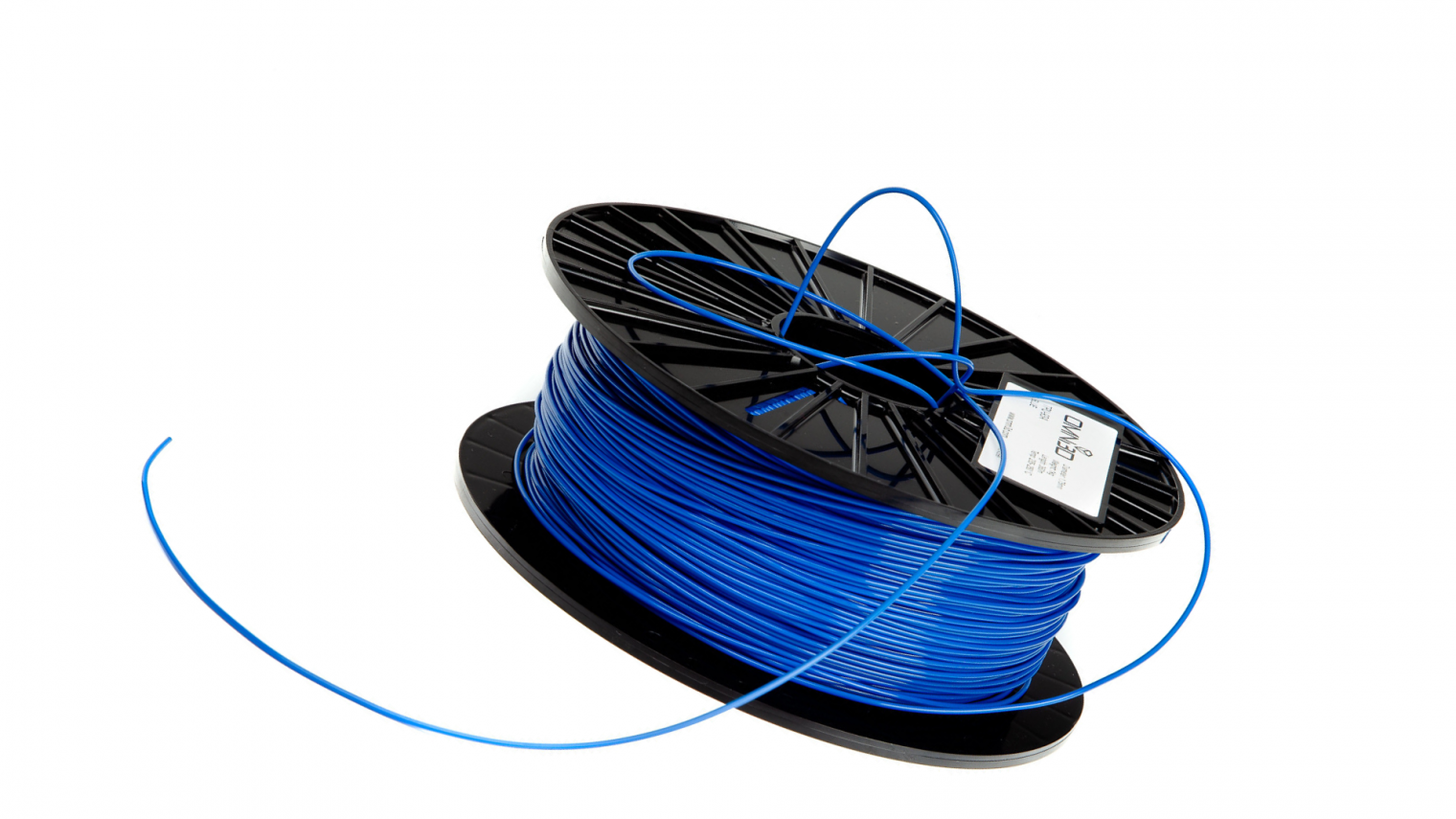

The FFF technology uses thermoplastics such as PLA-36, CF-PA12 or ABS-42 in the printing process. The material is fed in the form of a plastic string called a filament. The printing process consists of embossing the filament and applying it layer by layer of material, until the final model is created.

What is 3D printing in FFF technology – this question is answered by Omni3D specialist, Krzysztof Kardach, Chief Technologist (subtitled):

FFF 3d printing technology in industrial production

FFF technology is the best 3D printing method applicable in industry, automotive, architecture, aviation and even food industry. The combination of an industrial 3D printer with a wide range of filaments is a possibility to replace traditional production methods with 3D printing, thus saving costs and time.

Do you want to see more about the possibilities of 3D printing in FFF technology?

Order a trial print from Omni3D or contact us and ask for details!